In the fast-paced and demanding food preservation and retail industry, commercial refrigeration systems are essential and serve multiple functions. Understanding the components of these systems is not only a technical necessity but also a key factor in effectively managing any food-related business.

This blog aims to demystify the complexities of commercial refrigeration systems. It serves as a vital resource for business owners, managers, and technicians who depend on these systems to safely and efficiently store perishable goods.

By delving into the roles of compressors, condensers, evaporators, expansion valves, refrigerants, and thermostats, we hope to provide a thorough understanding of how each part contributes to the smooth operation of a commercial refrigerator.

What is a Commercial Refrigeration System?

commercial refrigeration system is a vital and advanced component in the food and beverage industry, designed to store and preserve perishable items in optimal conditions. Unlike regular household refrigerators, these systems are built to endure the demands of commercial environments such as restaurants, grocery stores, and food processing plants.

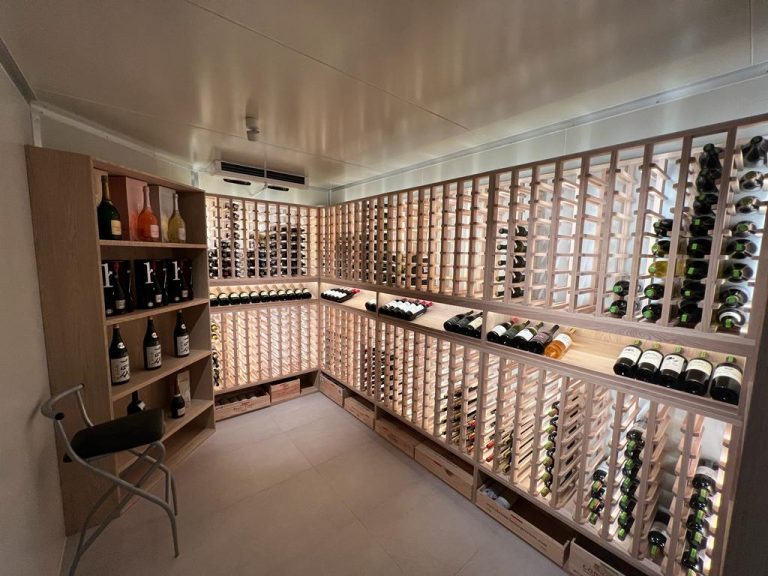

The main purpose of a commercial refrigeration system is to maintain a consistent, cold temperature, ensuring food stays fresh, safe, and free from bacterial growth. These systems come in various forms, including walk-in coolers, reach-in refrigerators, and display cases, each catering to specific storage needs and operational requirements.

Designed for larger capacities, frequent use, and precise temperature control, commercial refrigeration systems rely on a series of specialized components like powerful compressors, durable condensers, efficient evaporators, and accurate expansion valves. Together, these components work in harmony through a refrigeration cycle, where the refrigerant absorbs and releases heat to cool the unit’s interior. Additionally, modern systems often include advanced features such as digital temperature controls and automated defrost cycles, boosting efficiency and user convenience.

One key aspect of commercial refrigeration systems is their adaptability to different business needs. For example, a restaurant’s refrigeration requirements may differ from those of a floral shop or medical facility. As such, these systems are versatile, available in various sizes, styles, and features.

From glass-door merchandisers that showcase products to space-saving under-counter units, commercial refrigeration systems play a crucial role in various business settings. With the increasing focus on energy efficiency and sustainability, today’s commercial refrigerators are also designed to be more environmentally friendly, reducing energy consumption while maintaining high performance.

What are the Differences Between Commercial and Industrial Refrigeration?

The refrigeration needs of businesses can vary significantly depending on the industry and application. While both commercial and industrial refrigeration systems serve as the primary function of cooling and preserving products, there are several key differences between them.

Differences in Design and Components

Commercial refrigeration systems are designed for frequent use in customer-facing environments, such as restaurants, supermarkets, and convenience stores. These systems prioritize easy access and aesthetic appeal, often featuring glass doors for product display and compact sizes for better space efficiency. The components are optimized for quick cooling and consistent temperature maintenance, even with frequent door openings.

On the other hand, industrial refrigeration systems are built for larger-scale operations, such as food processing plants and pharmaceutical storage. These systems are more robust, with larger compressors and condensers built for more intensive, continuous cooling. They focus on functionality rather than aesthetics, emphasizing long-term storage and stability over frequent access.

Industrial refrigeration systems also tend to incorporate specialized components like ammonia-based refrigerants or advanced automation systems. These elements are selected for their ability to handle large volumes and maintain consistently low temperatures. Due to the scale and complexity, industrial systems require more durable materials and engineering, setting them apart from their commercial counterparts in both design and component selection.

Differences in Applications

Commercial refrigeration is typically used in settings where the end consumer interacts directly with the unit, such as display refrigerators in a bakery or beverage coolers in a convenience store. These units are designed for retail environments and are optimized for short-term storage and easy access.

In contrast, industrial refrigeration systems are used in sectors where large-scale cooling and long-term storage are crucial. These include industries like agriculture (for producing storage), pharmaceuticals (for drug preservation), and food processing (where bulk storage at consistent temperatures is essential). Industrial systems are often part of a larger supply chain and are critical in maintaining the cold chain for perishable goods from production to consumption. They are built to operate under more demanding conditions and are more resilient to external temperature fluctuations and environmental changes. The scale of operation also differs, with industrial systems designed to cool larger spaces and volumes, often tailored to specific industry needs.

Differences in Maintenance and Repair

Maintenance and repair for commercial refrigeration systems are typically simpler due to their smaller size and less complex design. These systems require regular upkeep, such as cleaning coils, checking temperature settings, and ensuring door seals are intact. Repairs are often straightforward and can be performed on-site with minimal disruption to daily operations.

In contrast, industrial refrigeration systems require more rigorous maintenance because of their size and complexity. These systems are integral to business operations, and any downtime can have significant consequences. Maintenance typically involves a team of specialized technicians who perform regular checks on compressors, condensers, refrigerant levels, and system performance. Repairing these units can be complex and time-consuming, often requiring specialized parts and expertise. Preventive maintenance is essential in industrial settings to prevent system failures, which can lead to major product loss and operational delays. As a result, industrial refrigeration maintenance is more intensive and specialized than commercial refrigeration.

Components of a Commercial Refrigeration System

Understanding the components of commercial refrigeration systems is essential for anyone involved in food storage, retail, or hospitality businesses. These systems are complex assemblies, with each part playing a crucial role in ensuring the freshness and safety of stored products.

- Compressor: The compressor is the “heart” of the refrigeration system, responsible for compressing the refrigerant, raising its temperature and pressure. This step is vital as it kick-starts the refrigeration cycle, allowing the system to transfer heat from the interior to the external environment. A well-functioning compressor is key to the efficiency and longevity of the system.

- Condenser: The condenser follows the compressor in the refrigeration cycle, cooling the refrigerant and converting it from a gas to a liquid form. It is usually located at the back or bottom of the unit and is crucial for maintaining the efficiency of the refrigeration cycle, ensuring continuous cooling of stored items.

- Evaporator: The evaporator is where the cooling effect occurs. Here, the liquid refrigerant absorbs heat from inside the refrigerator and evaporates, lowering the temperature within. The evaporator’s efficiency is essential for maintaining the desired temperature and preserving the stored products.

- Expansion Valve: The expansion valve controls the flow of refrigerant into the evaporator, lowering its pressure and temperature. This controlled release is vital for the refrigerant to effectively absorb heat within the evaporator, and its regulation is critical for the system’s overall efficiency and temperature control.

- Refrigerant: The refrigerant is essential to the system, circulating through the compressor, condenser, expansion valve, and evaporator. It undergoes phase changes from liquid to gas, absorbing and releasing heat in the process. The choice of refrigerant affects the system’s performance, efficiency, and environmental impact. Newer, eco-friendly refrigerants are becoming increasingly popular as industries shift towards more sustainable practices.

- Thermostat: The thermostat is the control unit for regulating the temperature in commercial refrigeration systems. It senses the temperature inside the unit and activates or deactivates the compressor to maintain the desired temperature range. A precise and responsive thermostat is critical for efficient operation and ensuring the proper preservation of stored products.

How Can Ventco Help?

Ventco specializes in offering high-quality, refurbished commercial refrigerators in Singapore. With a deep understanding of the components that make up commercial refrigeration systems, we utilize our expertise to refurbish units that not only meet but exceed industry standards. Our process involves thorough inspection, repair, and replacement of key components, ensuring that each refrigerator operates with the efficiency and reliability required by modern businesses.

Our expertise goes beyond just refurbishment. We are committed to offering businesses cost-effective solutions without compromising on quality. By choosing a refurbished unit from Ventco, businesses can enjoy the benefits of top-tier commercial refrigeration systems at a fraction of the cost of purchasing new equipment.

This approach not only helps businesses save money but also supports environmentally sustainable practices by extending the life of existing equipment. Our wide range of refurbished units comes in various sizes and styles, catering to the diverse needs of businesses. Whether you’re managing a small café or a large supermarket, Ventco has the expertise and inventory to provide a refrigeration solution that perfectly meets your business’s needs.

Looking for reliable cold room contractor in Singapore? Ventco offers a wide range of cold room solutions. Contact our experts to gain more information today!

https://ventcoengrg.com.sg/our-services/refregeration/modular-walk-in-coldrooms/