Designing a cold room isn’t just about making a space cold — it’s about ensuring consistent temperature, efficient energy use, and long-term protection of your products. In Singapore’s humid climate and space-limited commercial environments, selecting the right cooling capacity and storage volume is key to running a safe and cost-effective operation.

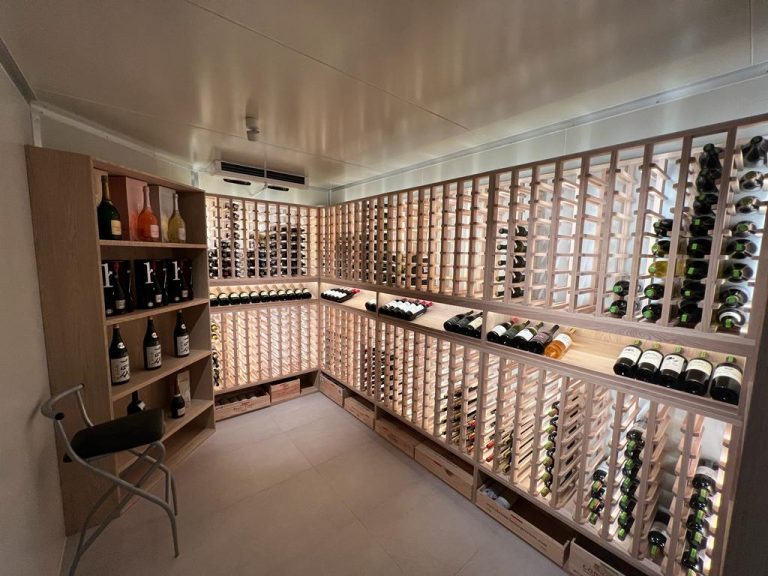

Whether you’re in F&B, logistics, pharmaceuticals, supermarkets, hotels, or require a residential/commercial wine cellar, this guide will help you determine the ideal cold room capacity for your needs.

- Understand What You’re Storing

Different products require different storage conditions.

| Product Type | Typical Storage Temperature | Considerations |

| Fresh Produce | +2°C to +8°C | High humidity to avoid dehydration |

| Meat & Poultry | -18°C and below | Fast chilling/freezing capacity needed |

| Dairy & Bakery | +2°C to +5°C | High stock turnover |

| Seafood | -20°C to -28°C | Strict temperature consistency |

| Vaccines/Pharma | +2°C to +8°C / -20°C | Regulatory compliance |

| Wine Storage | +12°C to +18°C | Strict humidity + vibration control |

Incorrect sizing = unstable temperatures → product spoilage → financial loss.

- Calculate Storage Volume Properly

Cold room size must match both current needs and future growth.

Ask yourself:

- How many pallets, cartons, or bottles are stored daily?

- How often will stock be replenished?

- Do you need space for employees to move inside?

A good rule: Only 60–75% of the internal volume should be used for storage to allow proper airflow.

Tip: We design modular cold rooms optimized for Singapore’s compact retail kitchens and storage areas — maximizing usable space without compromising cooling efficiency.

- Consider Heat Load Factors

Cooling capacity isn’t determined by room size alone. These factors add heat to the room:

- Door openings & foot traffic

- Fresh vs. pre-chilled goods

- Lighting heat emission

- Refrigeration equipment location (indoor vs. outdoor)

- Insulation thickness & panel material

- Ambient Singapore temperature (32°C+ outdoors)

Improper heat load calculation leads to:

– Compressor overworking

– Excessive energy bills

– Reduced equipment lifespan

We use accurate heat load calculations to ensure the system runs efficiently in local climate conditions.

- Plan for Operational Workflow

Ask:

- How frequently are goods accessed?

- Do you need shelving, pallet racking, or blast freezing?

- Will storage expand during festive seasons or business growth?

We typically recommend modular cold rooms so expansions can be done easily later.

- Factor in Compliance & Safety

In Singapore, food storage must comply with:

- SFA food safety requirements

- NEA & BCA building and mechanical ventilation guidelines

Wine cellars must also control:

- Humidity (50–70%)

- Vibration & light exposure

We ensure all cold room and refrigeration projects meet local standards.

- Energy Efficiency Matters

Electricity is a major operating cost in Singapore.

Choose:

- High-efficiency compressors

- Digital temperature controls

- Eco-friendly refrigerants

- Automatic door closers

- LED lighting

With smart system design, you can reduce energy consumption by 10–25% annually.

Why Work with Ventco Engineering?

✔ Singapore-based expertise

✔ Custom cold rooms for F&B, retail, logistics, pharmaceutical & industrial sectors

✔ Premium wine cellar design for homes, restaurants & hotels

✔ After-sales service & maintenance support

✔ Fast installation using modular panel systems

Start with a Free Consultation

If you’re planning a new cold room or upgrading your existing facility, Ventco Engineering can provide:

- On-site assessment

- Capacity planning

- Layout & workflow optimization

- Cost-efficient system design

📞 Contact our experts today to build a cold room that preserves product quality while reducing operating costs – perfectly suited for Singapore’s business environment.