Before food reaches our dining tables, it undergoes a complex and intricate journey. In this article, we focus on the critical aspect of the cold chain – cold storage warehousing. This important step ensures food stays fresh and safe, slowing nature’s course to make it possible for nutritious food to reach every corner of the globe.

What is a Cold Storage Warehouse?

The cold storage warehouse is perhaps the most important element of the cold chain, making the entire process feasible. These temperature-controlled facilities come in various sizes and locations, offering diverse services to maintain optimal conditions for food storage. The interconnected network of these refrigerated buildings ensures food is stored safely while awaiting its next stage in the supply chain.

Cold storage warehouses are highly insulated structures designed to retain cold air and keep out warm air. They rely on advanced HVAC systems to maintain cool or freezing temperatures and are carefully constructed and maintained to preserve the integrity and efficiency of the building.

From traditional, large-scale warehouses to state-of-the-art automated systems, these facilities are tailored to meet the specific needs of the products they store.

Different Types of Cold Storage Warehouses

Cold storage warehouses are designed to fulfill specific needs, and various types exist based on the type of products being stored.

Refrigerated and Frozen Warehouses

Cold storage warehouses are generally categorized into refrigerated and frozen facilities. Many warehouses offer both types of storage in separate areas of the building. Refrigerated rooms maintain a temperature range of 0° – 10°C, suitable for fresh produce like fruits, vegetables, meats, and dairy products.

Frozen and blast frozen products, which require temperatures ranging from -30° to 0°C, are kept in different sections. These products, such as ice cream, popsicles, and frozen fruits and vegetables, benefit from blast freezing—a rapid process that helps them reach and maintain safe frozen temperatures.

Automated Warehouses

The future of cold storage lies in automation. Next-generation cold storage warehouses are increasingly incorporating robotics and AI to optimize product receiving and placement. These technologies streamline operations, reducing turn times and increasing storage capacity.

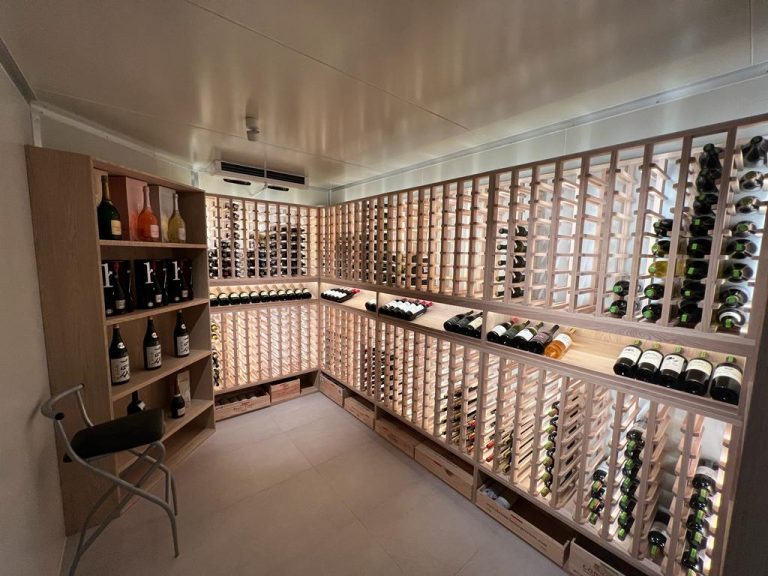

Customized Cold Storage Warehouses

We recognize that not all food products or customers have the same storage requirements. That’s why Ventco offers customised solutions to accommodate just about any cold storage requirements. Our tailor-made cold room systems are built to meet customer’s specific needs, whether it’s for meeting the stringent conditions needed for frozen seafood, ripening fruits like apples and bananas or anything in between. Our bespoke refrigeration systems are designed to meet the unique demands of different food items.

The Essential Role of Cold Storage Warehousing

Cold storage warehouses are the heart of the cold chain, enabling food to travel from one part of the world to another while maintaining its quality, safety, and nutritional value. Whether refrigerated or frozen, automated or traditional, these facilities help slow nature’s clock, allowing food to journey across continents and oceans. This global network of cold storage warehouses plays an essential role in delivering fresh, safe, and nutritious food to our tables.